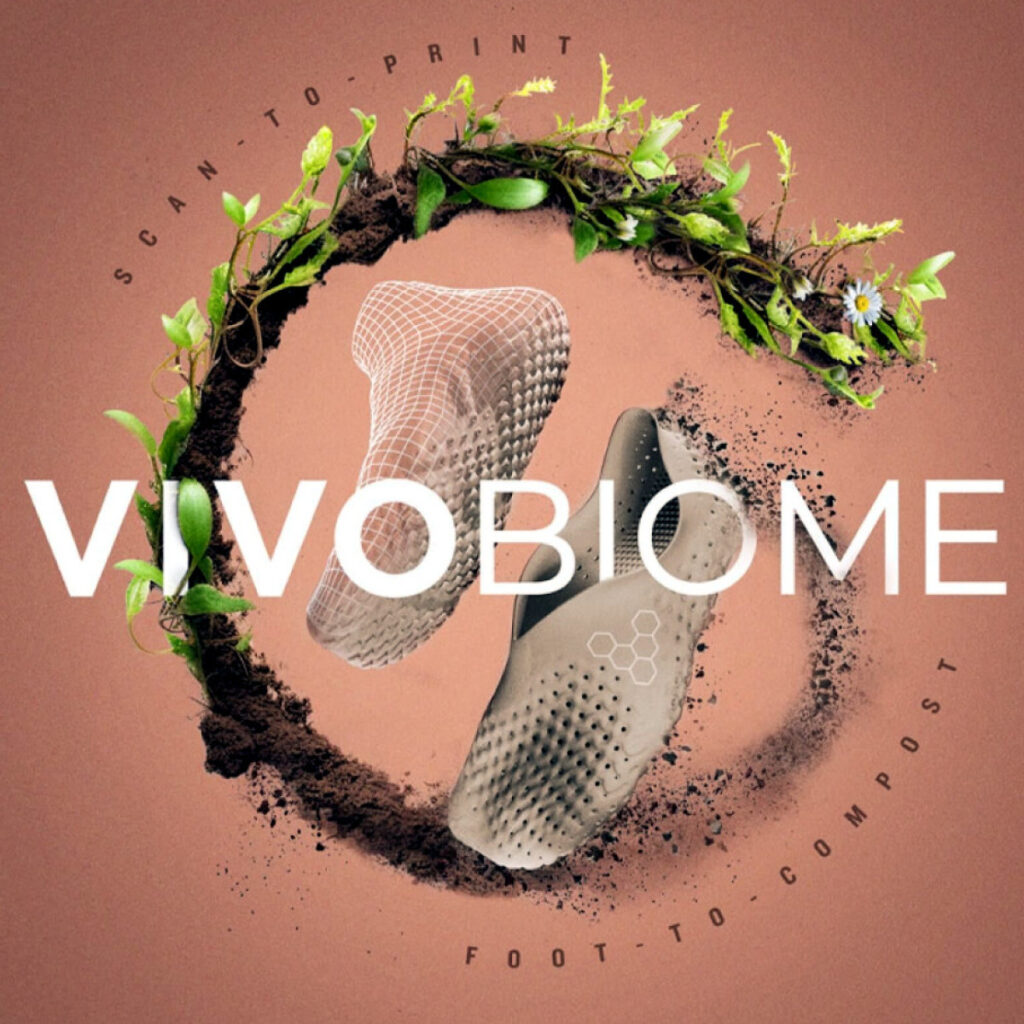

Vivobarefoot & Balena Take Next Step Toward Regenerative Barefootwear

3 min read

The footwear manufacturer and material-science company aim to deliver the

world’s first 3D-printed, made-to-measure footwear that is fully compostable.

Global natural health lifestyle brand

Vivobarefoot recently announced a partnership

with circular material-science startup

Balena — which developed its

biobased, compostable, recyclable, thermoplastic materials range

BioCir® for use in a variety of

industries. The partnership vision is footwear made-to-order, made-to-measure,

made locally, and made to be compostable and recyclable — an antidote to the

vast amounts of waste created by conventional shoe production.

Over-designed and over-produced, conventional shoes are now mass-consumed,

damaging to our

bodies,

and creating massive waste. In short, shoes are trashing our feet and our planet

— they make our feet weak; are made through off-shore, through often

less-than-ethical supply

chains;

and 12 billion pairs end up in

landfill every year.

The journey toward a circular end-of-life system for footwear faces a

significant challenge rooted in the intricate nature of shoes — both in their

design intricacy and the diverse materials used during manufacturing. The

complexity arises from the multitude of components — making recycling and

reintegrating used shoes into the supply chain a formidable task. Nike

recently unveiled its first fully circular shoe, designed for disassembly and

recyclability;

but industrywide efforts to change the wasteful ways shoes are made remain

piecemeal.

Vivobarefoot and Balena are hoping to prove that biodegradable material

alternatives and on-demand design and production offer a viable solution to the

challenges posed by the current limitations of recycling in the footwear

industry.

“The world doesn’t need new shoes. We need a new system and new materials,”

said Vivobarefoot co-founder Asher

Clark. “This future is

literally at our feet and this footwear will enable us to reconnect to nature,

move as nature intended and return footwear to nature when you’re done.”

Vivobarefoot acknowledges that it is part of the problem but also part of the

solution, thanks to initiatives such as

VivoBiome

— its scan-to-print, circular design platform that enables rapid prototyping to

save development and lab time, labor, and materials waste — revolutionizing the

shoe design and production process.

Now, Vivobarefoot aims to take this innovation a step further with the

incorporation of Balena’s BioCir flex

material — a compostable, biobased,

recyclable, thermoplastic material with advanced performance properties that

Balena developed for scaled durable goods production, including footwear, on a

mission to create a circular model for consumer industries.

Founded in 2020, Balena is on a mission to create a circular model for durable

consumer goods and solve one of the biggest challenges for achieving circular

models across industries: the products’ end-of-life. Founder David

Roubach

told Business Focus

he’s excited about the partnership with Vivobarefoot — which inspired the

creation of his own company.

“About 4 years ago, I heard Asher on stage with his amazing vision for

VivoBiome; and it was clear to me that in order to enable consumer product

companies to achieve true sustainability, there is a need to advocate for a

clearer circular economy model with a fundamental change in the materials we

use — and that’s what Balena is all about,” he said. “Seeing that collaboration become a

reality fills me with immense pride.”

BioCir flex maintains high flexibility, similar to TPU (thermoplastic

polyurethane — a standard filament for 3D printing), providing reliable and

long-lasting 3D-printed products. At the same time, it is biobased and

industrially compostable, reducing the environmental impact of discarded prints

— and for the first time, enabling 3D printing of flexible and durable items

while giving them the unique property of biodegradability, whereas traditional

TPU is non-biodegradable and contributes to plastic waste.

Prototypes are being made using a patented scan-to-print, computational design

system that, if scalable, will enable them to make bespoke, on-demand footwear

for individuals — not mass markets.

“Our goal at Vivobarefoot is to develop performance footwear that is both

durable and fully compostable,” Clark says. “This first-of-its-kind

collaboration moves us a step closer to that goal — giving us the ability to

make product design and development decisions based on science, which we’ve

never been able to do before.”